Umatshini weTshokholethi yeeChips ezizenzekelayo

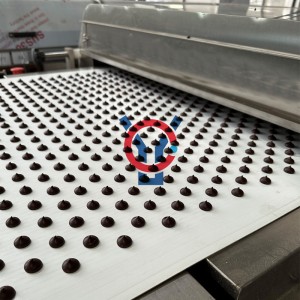

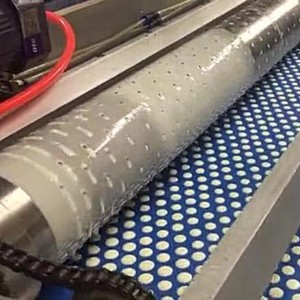

Umatshini wokuDipha wetshokholethi /Iitshiphu zetshokholethi zoMtshini woMgcinisisixhobo esizinikeleyo sokwenziwa kweetships zetshokholethi kwimilo encinci yethontsi okanye iqhosha.Ingasetyenziselwa ukubeka i-chocolate pastes ngokufaka intloko kwibhanti yokuhambisa i-PU kunye nokuhanjiswa kweemveliso kwi-tunnel yokupholisa ukupholisa kunye nokuchithwa ngokuzenzekelayo. Umshini wokwenza i-Chocolate Chip uneenzuzo zokumisela isixa esichanekileyo, ukusebenza lula kunye nomthamo omkhulu wokuvelisa.Izinto zokubumba zetshokholethi ziwisa umatshini wokwenza intsimbi okanye iplastiki yepolycarbonate, iplastiki yepolycarbonate inamandla amahle kakhulu kunye noburhabaxa, kunye nomthamo wobushushu obuthile kunye ne-thermal conductivity yepolycarbonate iyafana netshokholethi, kwaye inomsebenzi ongcono wokudiliza.Ukongeza kokusetyenziswa kolu hlobo lwepleyiti yokubumba, ukusetyenziswa ngakumbi kwepleyiti ye-porcelain, kuba inoburhabaxa obugqwesileyo kunye neempawu ezilungileyo zokudiliza.Kukho iindlela ezimbini zokuvelisa iitshiphusi zetshokholethi.Enye indlela yiPneumatic depositor okanye i-servo motor depositor, enye indlela kukuqengqeleka ukwenza umatshini wetships.

| Umzekelo

Iiparamitha zobuGcisa | 400 | 600 | 800 | 1000 | 1200 |

| Ububanzi bebhanti lokuhambisa (mm) | 400 | 600 | 800 | 1000 | 1200 |

| idiphozithi isantya (amaxesha/min) | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 |

| Ubunzima obunye bokulahla (g) | 0.1-3 | 0.1-3 | 0.1-3 | 0.1-3 | 0.1-3 |

| Ubushushu beTonelo yokupholisa(°C) | 0-10 | 0-10 | 0-10 | 0-10 | 0-10 |

| Ubude bomatshini (m) | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 |

I-Chocolate Chip Depositor ivumela idiphozithi yetshokolethi kunye nethokoleta ikhompawundi amathontsi kunye chips kwiimilo ezahlukeneyo kunye nobunzima, ukusuka 0.1 ukuya 5 grams.Ezi ntlobo zeemveliso zilungele ukubonelela ngamashishini kunye nokunyibilika okulandelayo, ukuhlobisa kunye nokusetyenziswa kwezinye iimveliso, ngakumbi ii-cookies kunye ne-ice creams.

I-Chip Depositor Line ibandakanya intloko ye-depositor eneebhatyi ezimbini exhotyiswe ngokulawula ubushushu kunye ne-fixed-speed agitator.Ukunyakaza kwentloko kulungelelaniswa kunye nebhanti esetyenziselwa ukuqokelela iimveliso ezigciniweyo.Umgca ukwabandakanya inkqubo yokunyusa ibhanti yediphozithi evumela iimo ezahlukeneyo zokulahla.Amathontsi athunyelwa kwitonela yokupholisa kwangoko emva kwediphozithi.

Iipistons ezilawulwa yi-Servo okanye eziqhutywa yi-Pneumatic-Driven ziphucule ukuchaneka komlinganiselo.Elona nqanaba liphezulu letanki kunye nenkqubo yokujikeleziswa kwamanzi enejakethi ephindwe kabini ukuze kulawuleke ngokufanelekileyo amaqondo obushushu edipozithi.Kulula ukususa kunye nokucoca i-agitator yetshokolethi kunye netanki.Insimbi engenasici esetyenziselwa iindawo zokusebenza kunye nawo onke amacandelo adibana nemveliso.Isikrini esisebenzisekayo esine-PLC eyilwe ngokukodwa silawula zonke iiparamitha zokusebenza.

Lo matshini uguquguqukayo unokuhlengahlengiswa ngokulula ukuhlangabezana neemfuno zeemveliso ezintsha, ngokumalunga noyilo kunye notshintsho kwimilo okanye ubunzima, ngokutshintsha nje ibhodi yabahambisi, inkqubo ethatha imizuzu ukuyigqiba.Ifumaneka kwiindidi ezahlukeneyo zebhanti, ukusuka kwi-400 ukuya kwi-1200mm.